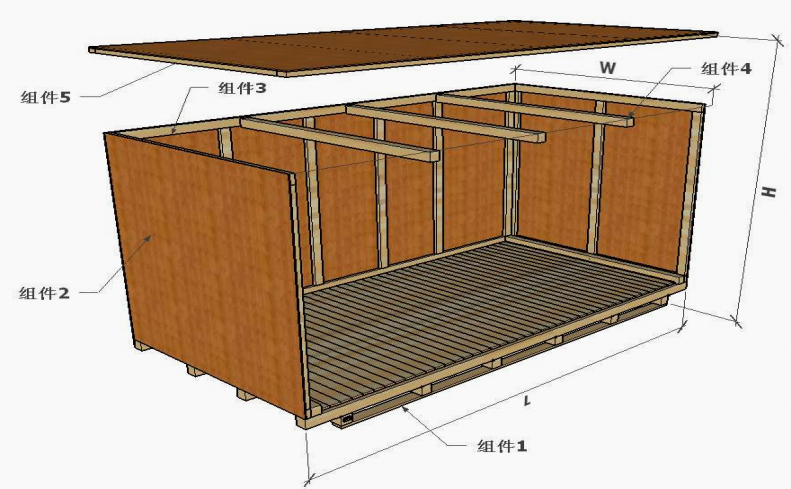

Large-size X-ray inspection system with Lead room package type

for ship optional wooden framed box structure

this project is one optional package type for oversea customer,and applied in some large-size X-ray inspection system with lead room from 2021 to 2025

I. Internal Fixation of Large-size X-ray inspection system with Lead room

1) Move the bottom slide rail to a corner and tighten it with packing straps.

2) Use a support to hold the upper mechanical arm in place and tighten it with packing straps to the bottom to prevent up and down vibration.

3) Place desiccant. Close the lead room door.

4) Cover with PE film and wrap with stretch film.

II. Fixation of Equipment Base

1) Prepare the base, place the bottom film of the vacuum bag, and use a forklift to place the lead room main body in the designated position.

2) Fix with packing straps and limit blocks to prevent equipment from shaking.

3) Place desiccant.

4) Put on the vacuum bag and vacuum it.

III. Box Board Sealing

1) Nail the end boards.

2) The lead room door needs to be fixed and directly pushed against the end board of the wooden box to prevent the lead room door from sliding.

3) Nail the long side boards and the top cover.

IV. Covering with Tarpaulin

1) Prepare the tarpaulin.

2) Nail the tarpaulin fixing strips.

The operation process of the wooden box for the operation table is basically the same, with the internal fixation process reduced.

V. Fixation of Frame Box

1) Fork the wooden box to the designated position of the frame box.

2) Support the wooden strips at the front and back and bind them with steel wire ropes.