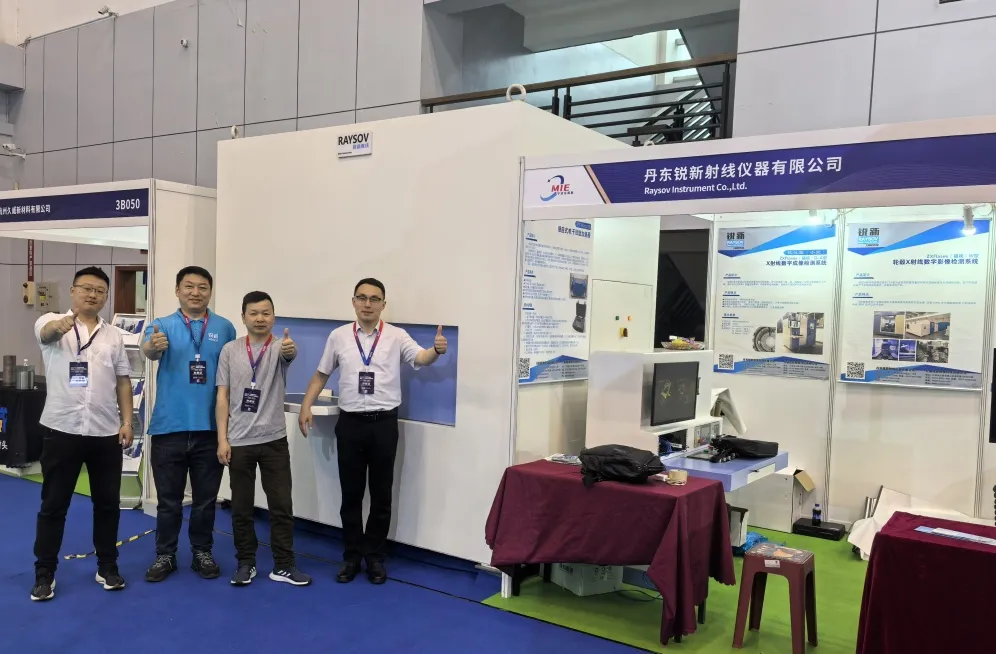

2025 Ningbo Metal Metallurgy Exhibition

RAYSOV X-ray Inspection System debuts to explore a new height of casting AI detection!

On April 23, the 2025 Ningbo International Metal Metallurgy Expo ended successfully at Ningbo International Convention and Exhibition Center.RAYSOV has unveiled its New ZXF DR/A industrial X-ray digital imaging (DR) inspection system, and has become the focus of this exhibition with its core technical strength and full Non-destructive testing industrial chain solutions.

Intelligent inspection reform and strong attack

ZXF DR/A DR X-ray inspection system use for casting research, defect analysis, quality control,High-level automation, high-accuracy detection , intuitive results

9-axis free motion detection without dead angles

Equipped with a 9-axis freedom motion mechanical system, it flexibly responds to the inspection requirements of various complex casting component, ensures that the inspection process is smooth and meets diverse industrial application scenarios.

Multi-directional detection perspective without boundaries

X-ray tube and X-ray detector operate independently, and can flexibly conduct multi-directional and multi-angle inspections around the test casting to ensure that every detail is not missed and there are no blind spots in the inspection.

Swivel dual-position board efficiency leap

Adopt with innovative slewing loading design, and the casting component loading and inspection are seamlessly connected, greatly improving the inspection efficiency and making the production process smoother and more efficient.

CNC one-click automatic intelligent detection+automatic defect recognition(AI detection)

Integrated CNC detection function, it supports "one-click" automatic detection of batch castings, greatly reducing manual intervention and improving the consistency and accuracy of detection. The automatic defect recognition (ADR) software is also optional, non-destructive testing defects in a smart way.