Industrial CT for lithium-ion battery measurement/analyzes advantages

Industrial CT

Industrial CT for lithium-ion battery

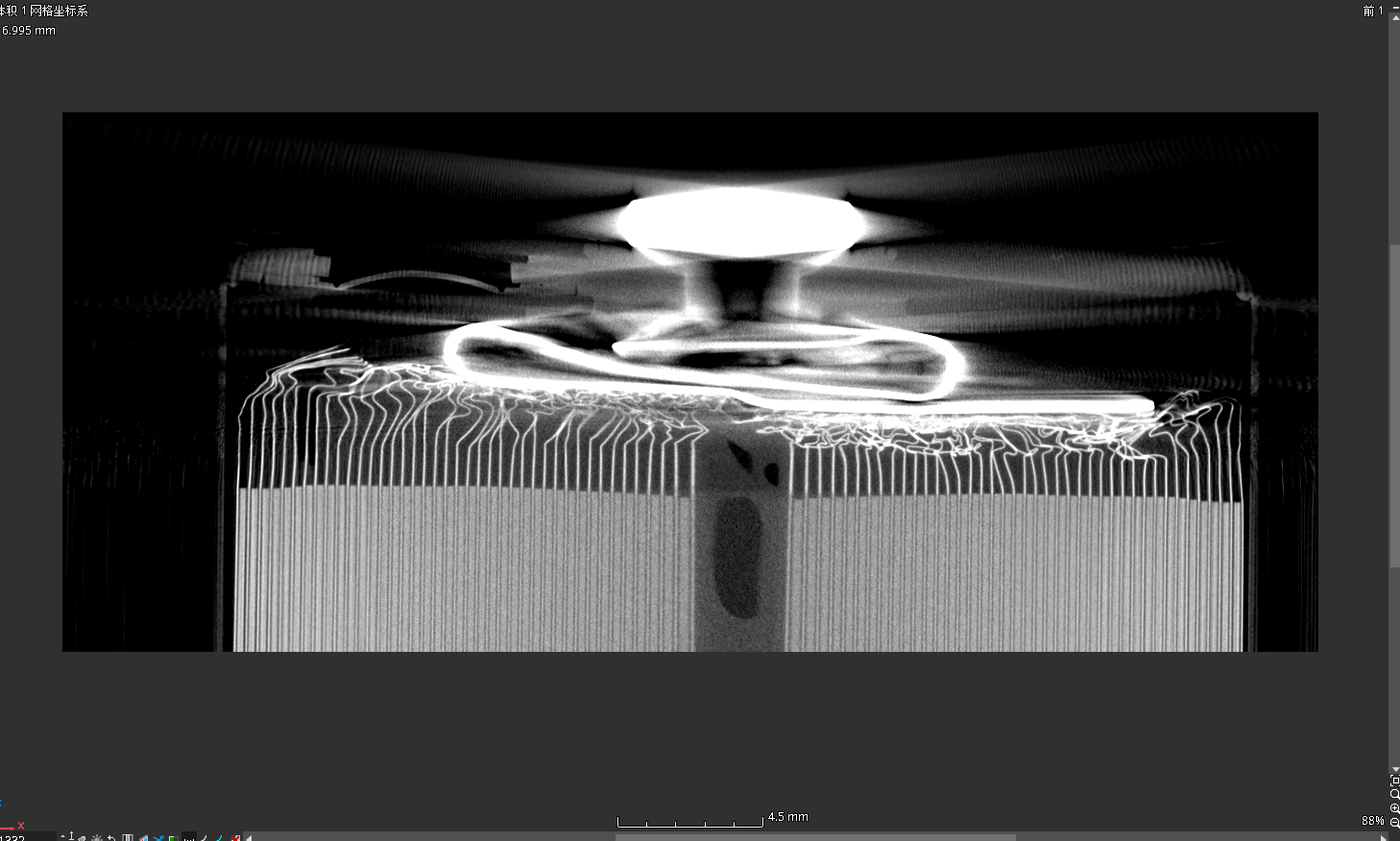

Check the open circuit of battery electrode ear welding

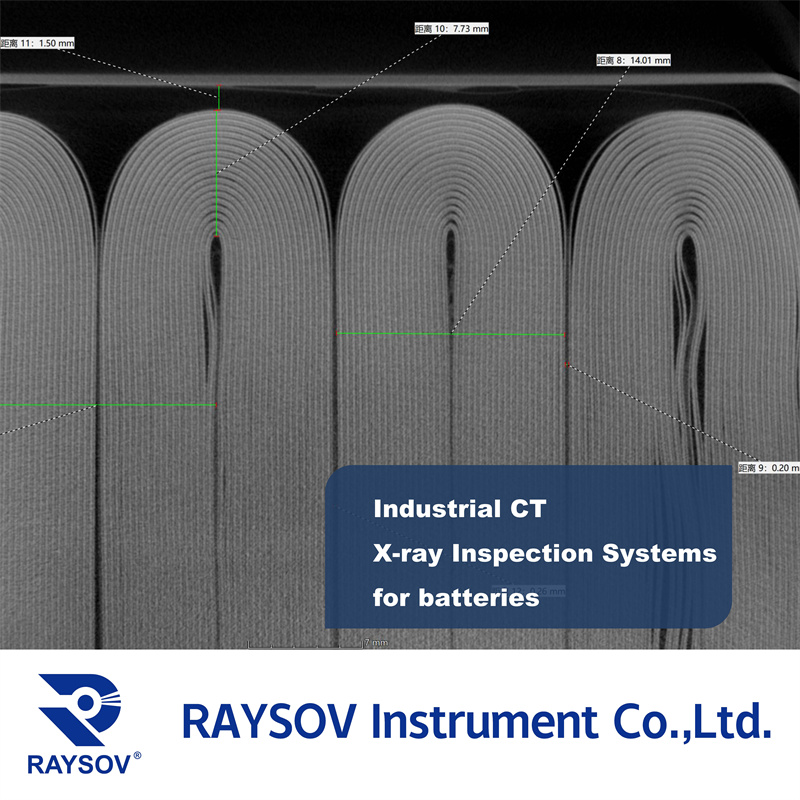

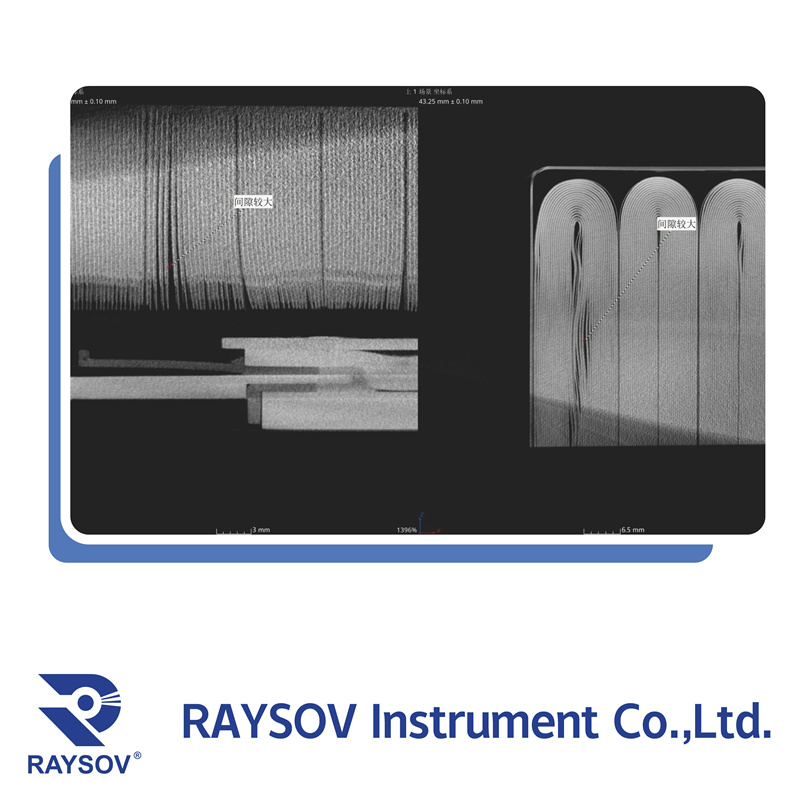

detect the stack alignment of stacked power cells

measure the negative layer beyond the positive length

find the maximum minimum and average

shell depth, roll size and other data

New energy vehicles have rapidly developed and occupied a certain market in the automobile industry due to their low-carbon, environmental protection and energy saving. Therefore, strengthening the development of new energy batteries can promote the better development of the new-energy automobile industry.

Industrial CT can intuitively display the internal structure, material composition and defect status of test object in two-dimensional sectional image or three-dimensional image.

Widely used in defect, location, size, density and distribution of composite materials, cutting-edge nondestructive testing technology,Industrial CT for lithium-ion battery has many advantages, including measurement/analyzes and improve the production process.

Industrial CT can detect the stack alignment of stacked power cells, the winding battery winding alignment, measure the negative layer beyond the positive length and find the maximum minimum and average and can also detect the winding alignment of the cylinder battery, shell depth, roll size and other data, as well as the inner structure of the cylinder battery stage ear and the positive and negative electrode sheet, detect the alignment of the square soft pack battery electrode positive and negative electrode plate and the angle of negative bending.

Check the open circuit of battery electrode ear welding, dislocation ratio of core positive and negative electrode, measurement of positive and negative electrode distance, welding and leakage of protection plate and positive and negative electrode. To ensure the quality detection of the battery at the same time, it can also directly distinguish inferior batteries, curb the circulation of unsafe and non-friendly batteries to the market from the source, and reduce quality risks.