Application of micro-CT (microfocus computed tomography)in composite material inspection

However, due to its unique structural characteristics and the influence of factors such as process technology during the manufacturing process, composite materials will inevitably produce defects and damage, which will affect the performance and structural integrity of composite materials and reduce their use life. It is crucial to use metrology-based industrial micro-CT systems to detect composite materials.

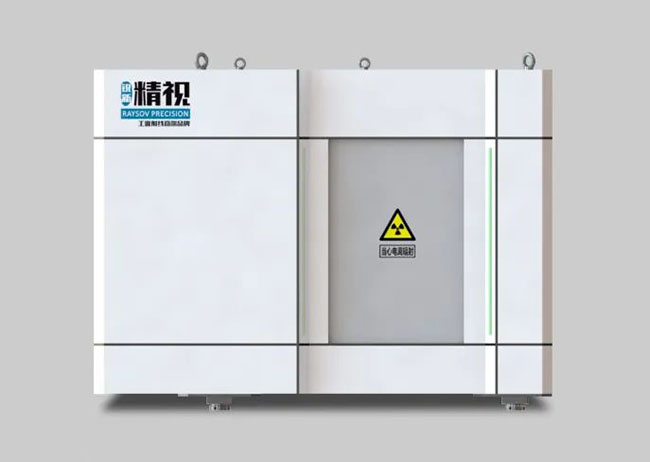

Industrial micro- CT system is intuitive because of its microfocus CT images. The grayscale of the image corresponds to the workpiece material, geometric structure, composition and density. It can not only obtain information such as the shape, location and size of the defect, but also determine the location of the defect when combined with density analysis technology. The nature of the defect space positioning, quantitative and comprehensive qualitative problems that have long troubled non-destructive testing(NDT) personnel has a more direct solution. LINAC high energy CT system images fully reproduce the composition characteristics of the large workpiece material. Therefore, three-dimensional micro-CT(microfocus computed tomography) images are of practical significance for the detection and analysis of complex structural parts, and dual-source dual-detector CT systems can be combined with CAD, CAM and other manufacturing technologies to form reverse engineering. These advantages are not available in other non-destructive testing(NDT) technologies, so micro-CT system is a common tool for testing composite materials.

If you want to know more about micro-CT , nano-CT flat-panel fast CT, in-situ loading CT, high-speed online CT and robot CT systems price and information or reverse engineering data.contact us