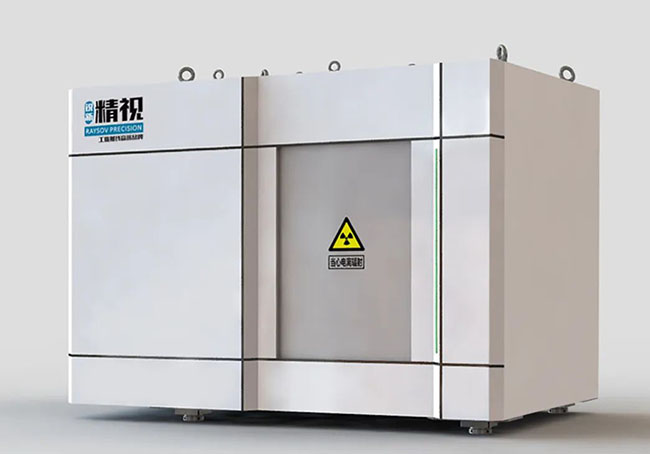

In the field of industrial manufacturing, accurate inspection of workpieces is always the core aspect to ensure product quality. ZXVoxel CT inspection system launched by RAYSOV is an industrial CT scanner designed for small, medium and irregular workpieces. With its wide applicability, high-precision inspection capability, flexible configuration and advanced software support, it brings significant efficiency and performance improvement to the industrial inspection field.

High precision inspection

The internal marble moving base and scale ensure high repeatability and stability, with dimensional accuracy ≤5μm.

Flexible Configuration of Radiographic Machine

Open micro-focused X-ray machine, support 160kV, 225kV, 300kV tube replacement, protection level meets protection requirements.

Efficient X-ray detector

Adopting imported flat panel detector, made of CsI cesium iodide, with 100μm pixels and 16bit high dynamic range, providing efficient image conversion.

Safety Protection

Self-shielding design, leakage radiation dose is less than 1μSv/h, ensuring safe operation.

Fine Parameter Adjustment

Full power curve kV, mA parameter adjustment to improve image contrast and quality.

Large range of high-precision motion control

Focal length of 800mm, 360° rotary motion stroke design for X, Y, Z axis and R axis, repeatability ≤ 4μm, servo drive control, precise positioning.

Compact automation design

Cabinet integrated, built-in panoramic camera, small footprint, high degree of automation.

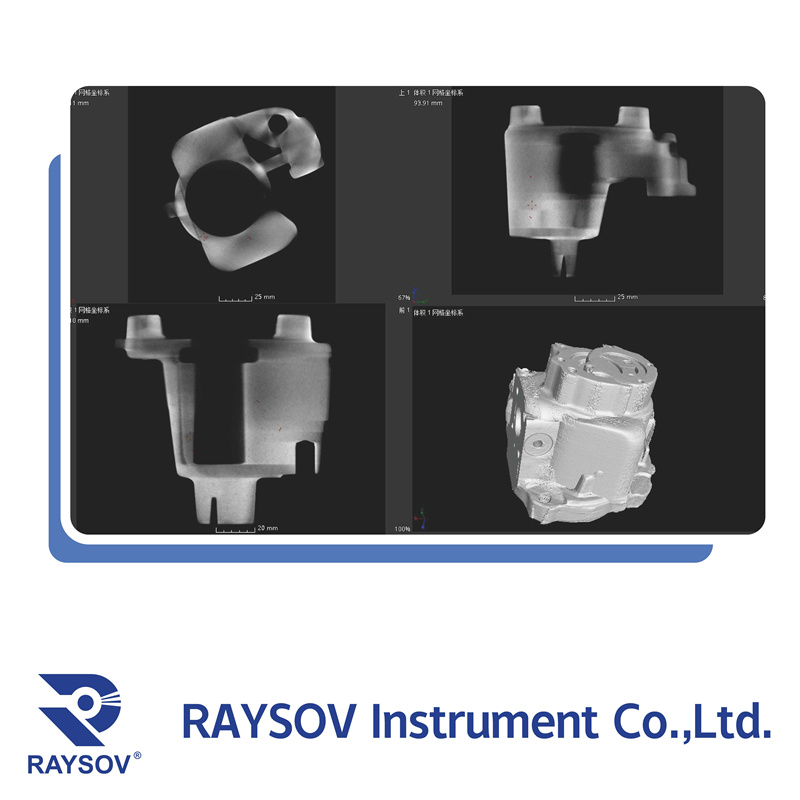

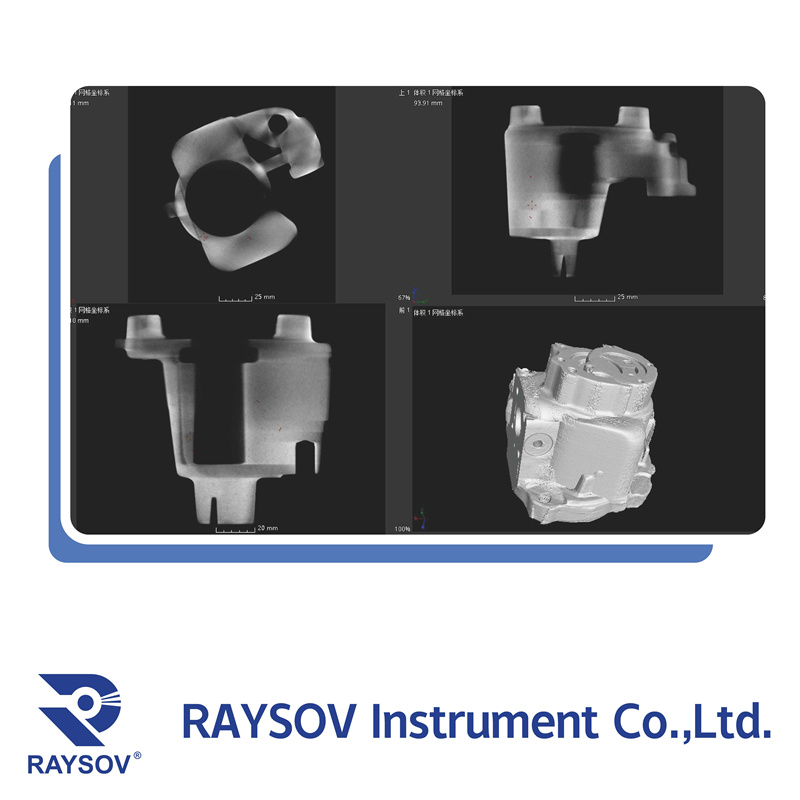

Advanced software support

German imported software with comprehensive image acquisition, processing and synchronous control functions.

Technical Advantages

Wide applicability

For non-metal, aluminium-magnesium alloys, steel and other materials, the ZXVoxel CT inspection system(CT scanner) can inspect workpieces up to a maximum diameter of 400 and a height of 500, which makes the inspection range wide and practical.High precision inspection

The internal marble moving base and scale ensure high repeatability and stability, with dimensional accuracy ≤5μm.

Flexible Configuration of Radiographic Machine

Open micro-focused X-ray machine, support 160kV, 225kV, 300kV tube replacement, protection level meets protection requirements.

Efficient X-ray detector

Adopting imported flat panel detector, made of CsI cesium iodide, with 100μm pixels and 16bit high dynamic range, providing efficient image conversion.

Safety Protection

Self-shielding design, leakage radiation dose is less than 1μSv/h, ensuring safe operation.

Fine Parameter Adjustment

Full power curve kV, mA parameter adjustment to improve image contrast and quality.

Large range of high-precision motion control

Focal length of 800mm, 360° rotary motion stroke design for X, Y, Z axis and R axis, repeatability ≤ 4μm, servo drive control, precise positioning.

Compact automation design

Cabinet integrated, built-in panoramic camera, small footprint, high degree of automation.

Advanced software support

German imported software with comprehensive image acquisition, processing and synchronous control functions.

Technical Parameters

Conclusion

Conclusion

RAYSOV is committed to providing our customers with cutting edge industrial inspection solutions.

ZXVoxel CT inspection system(CT scanner) is not only a collection of technologies, but also our commitment to the pursuit of ultimate precision.

Contact us for more information about our industrial CT inspection systems(CT scanner) and CT X-ray inspection solutions, and let our technology help you succeed in a new era of industrial inspection.