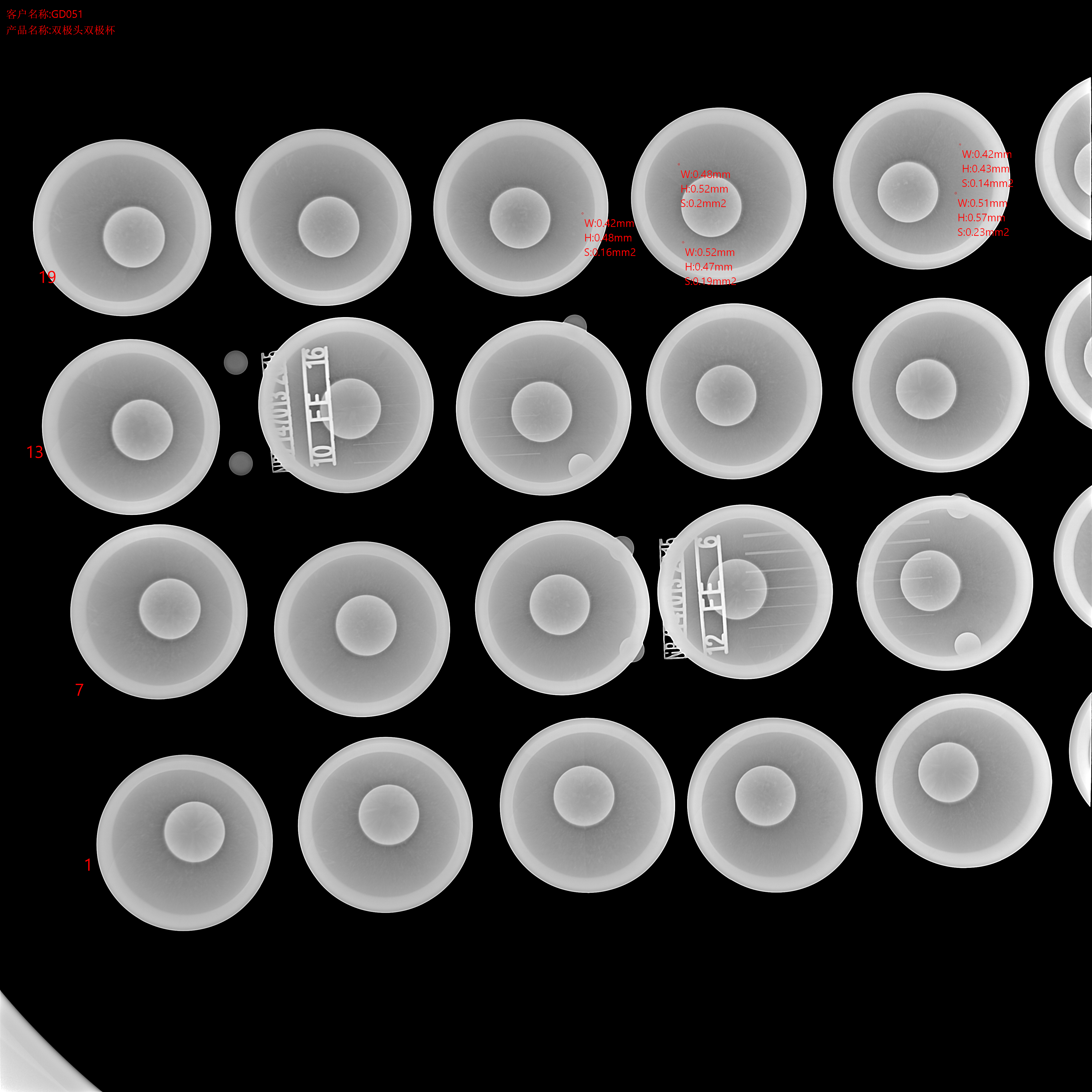

RAYSOV NDT X-RAY(non-destructive testing)high-precision 2D X-ray NDT inspection system for artificial joint test/medical instruments testing

(welding joint defect/casting flaws)

ZXFlasee DL-type X-ray NDT real-time digital imaging inspection system is a standardized special X-ray NDT inspection system specially developed for the X-ray NDT quality control on artificial joint test/medical instruments testing(welding joint defect/casting flaws)

for reference welding joint defect and casting flaws

Five common defect flaw detection X-ray NDT images.

X-ray images helps accurately determine the type and size of the defect.

Gas holes: Circular or elliptical black shadows, X-ray images with a darker center and gradually fading edges. Gas holes in automatic welding are mostly distributed in the center of the weld seam.

Inclusions: Irregular black shadows with distinct outlines. Metal inclusions X-ray images appear as bright spots, while non-metallic inclusions appear as dark spots.

Lack of penetration: Fine straight black lines, X-ray images with neat edges on both sides, fixed at the root of the weld seam, and the width corresponds to the root gap.

Lack of fusion: Divided into three types - root (neat black line on one side), bevel (crescent-shaped black line), and interlayer (irregular light black shadow) in X-ray images.

Crack: Jagged fine black lines, wider in the middle and narrower at both ends in X-ray images