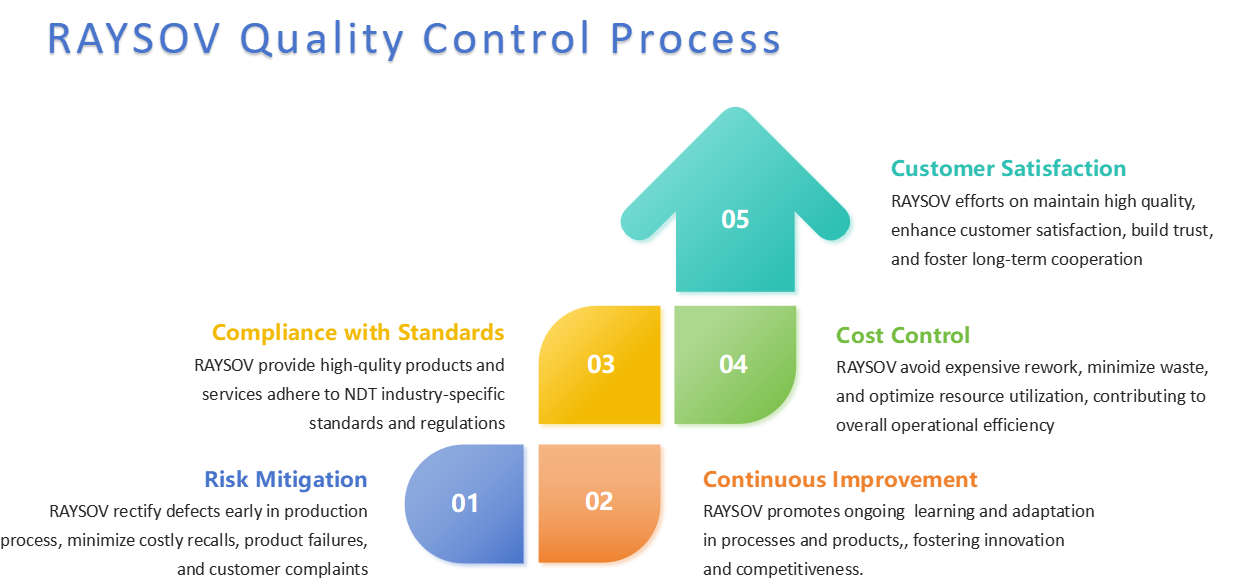

1. Customer Satisfaction:RAYSOV Quality Control Process is indispensable for ensuring that the final products or services meet or exceed customer requirements.With more than 15 years development and efforts on maintain high quality, enhance customer satisfaction, build trust, and foster long-term cooperation, satisfied customers become to be repeat buyers and advocates of RAYSOV brand.

2. Compliance with Standards: RAYSOV Quality Control Process is also including ensure that products or services adhere to NDT industry-specific standards and regulations. Meeting these standards not only reflects a commitment to quality but also helps the user in avoiding legal issues and regulatory penalties, ensuring ethical business practices.

3. Risk Mitigation: RAYSOV Quality Control Process plays the crucial role in risk reduction. It helps in identifying and rectifying defects early in the production process, minimizing the probability of costly recalls, product failures, and customer complaints, safeguards good reputation.

4. Cost Control: RAYSOV Quality Control Process for controlling costs associated with defects and errors. By detecting and addressing issues early on, avoid expensive rework, minimize waste, and optimize resource utilization, contributing to overall operational efficiency.

5. Continuous Improvement: RAYSOV Quality Control Process put continuous improvement in a important position. Through the identification of areas for enhancement in processes and products, RAYSOV promotes ongoing learning and adaptation, fostering innovation and competitiveness.