X-ray Electronic Component inspection systems

ZXFlaseeI Digital X-ray System for Electronic Component

Description

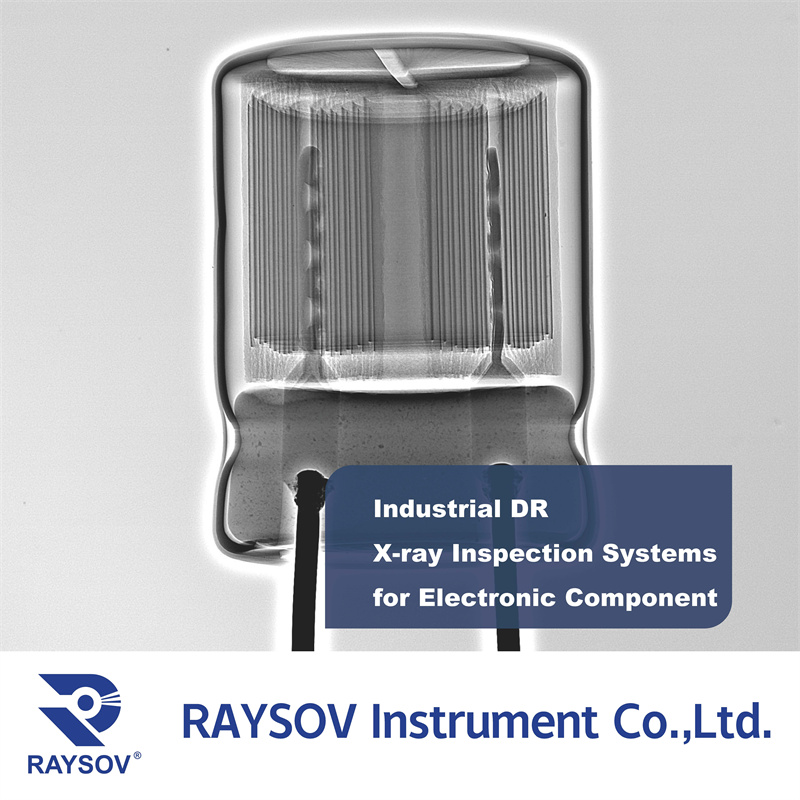

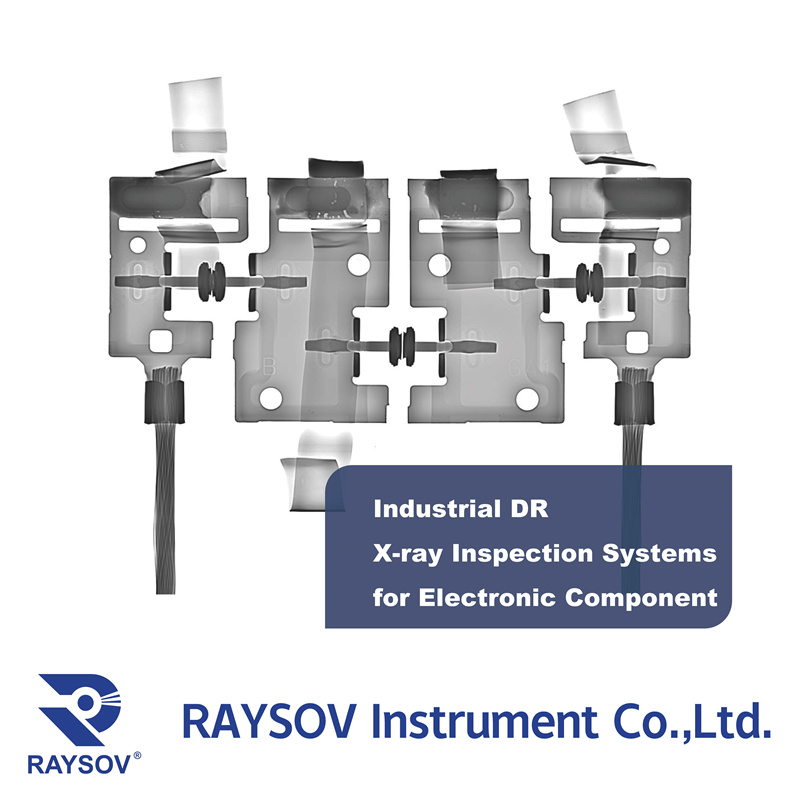

RAYSOV ZXFlasee Digital X-ray System for Electronic Component is suitable for non-destructive testing of Electronic Component, obtaining high-quality images of circuit layout, weld quality, visually presenting internal defects, assiting the quality control in Electronic circuit industry.

Features

Use HFHV generator,strong penetrating power and stable X-ray dose.Use wide range HD Flat-panel detector,high image sensitivity

Anti-arc,extend X-ray tube lifespan,keep the systems safe,reliable and durable

High-level automation,automatic transport test object, automatic positioning to detection area,optional ADR function,improve detection efficiency

Raylion image processing software,powerful filtering function one click,clear image quality,easy operate,one click inspection report

Strong structure,beautiful appearance,high-level protection, leakage dose <1μSv/h@30cm from lead room

Modular design,easy maintenance,system log can store fault message and self-diagnosis,reduce downtime costs

Composition

The system is mainly composed of seven modules, such as:

1. high frequency and high voltage(HFHV)X-ray source,

2. high resolution digital flat panel detector,

3. computer digital image processing system,

4. mechanical transmission system,

5. electrical control system,

6. monitoring system,

7. protective lead room.

All systems are designed to comply with the latest international radiation safety standards.

Application

X-ray Electronic Component Inspection Systems are used in various industries for the non-destructive testing and evaluation of products, components, and materials. These systems use X-rays to penetrate objects and capture images of their internal structures, enabling inspectors to identify defects, anomalies, and potential safety issues.

The system can also be upgraded to include CT (Computed Tomography) capabilities, allowing for even more detailed 3D analysis of the internal structures of these materials. This makes it particularly useful for quality control and failure analysis in various industries, such as automotive, aerospace, and intelligent manufacturing.